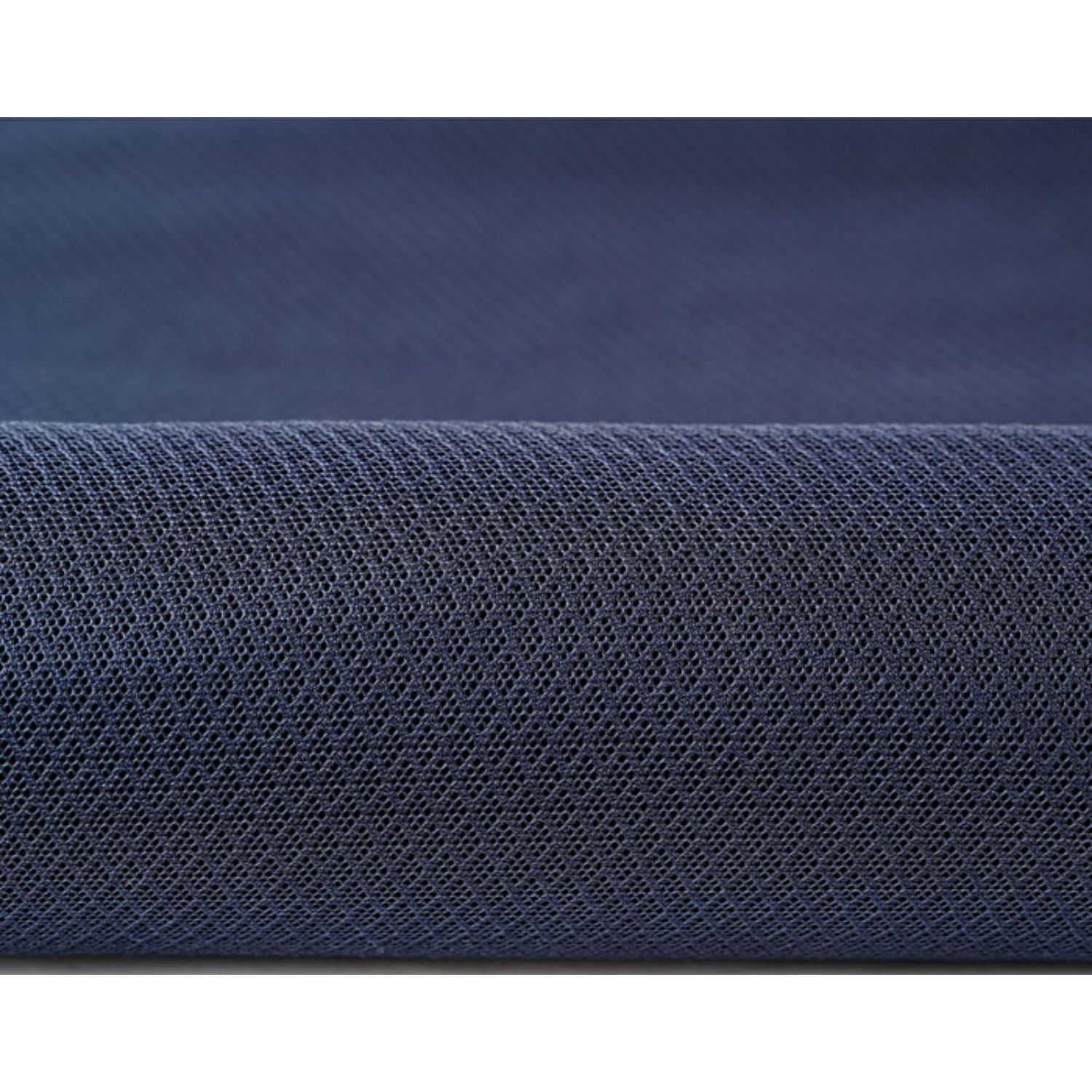

Tricot Knit :

Tricot fabric is soft, wrinkle resistant & has good drapability. Tricot knits are used for a wide verity of fabric weights & design. It makes light fabric weighting less than 4 ounce/square yard. Some examples of tricot fabric are sleepwear, boluses, dresses etc.

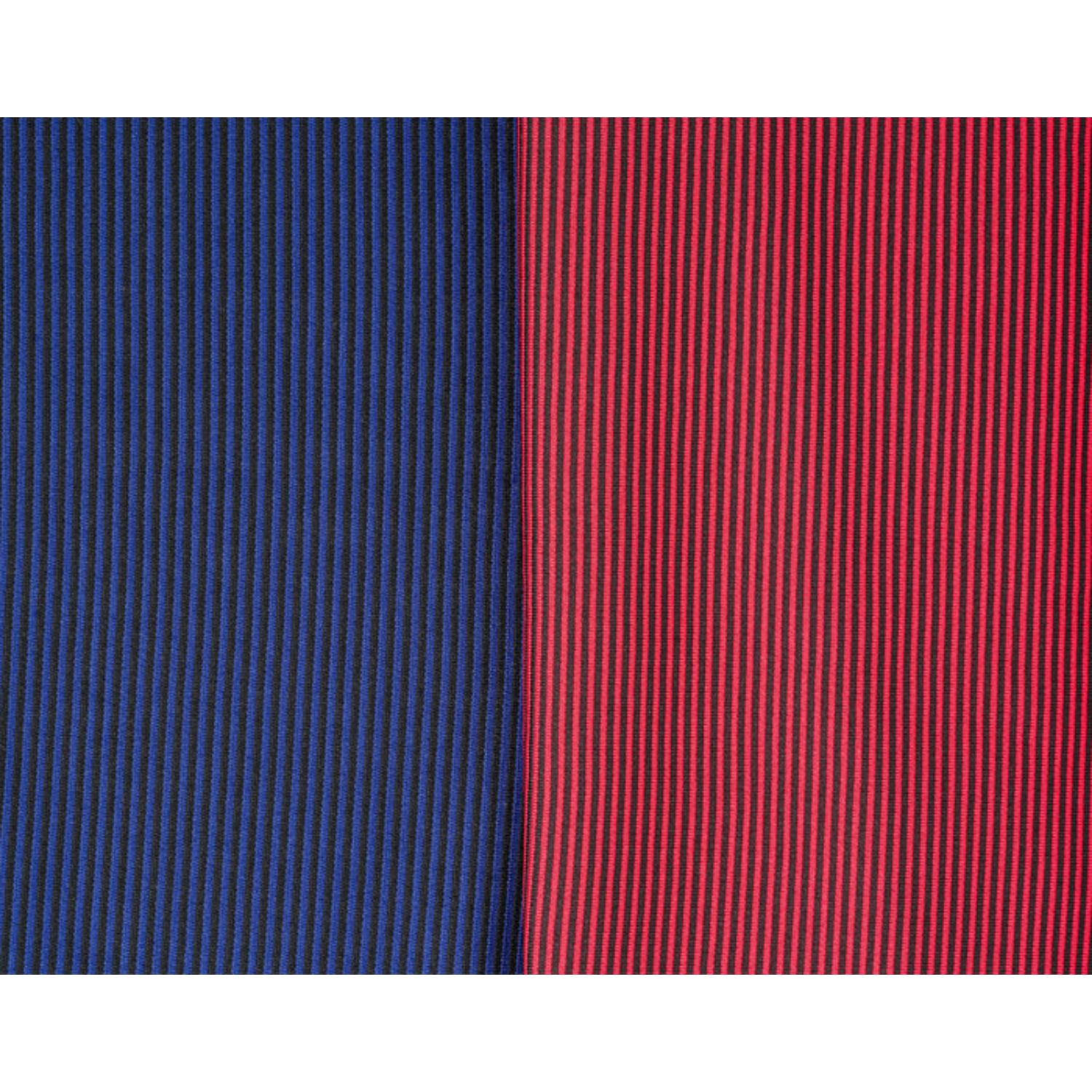

Raschel Knit:

The Raschel knit ranks in importance of production with tricot but it makes varieties of products ranging from laces, power nets for foundation garments, swimwear to carpets. Raschel knitting is done with heavy yarns & usually has a complex lace-like pattern.

Crochet Knit:

This basic stitch is used in hand crochet. This construction is used in a wide variety of fabrics ranging from nets & laces to bed spreads & carpets, various types of edgings or trimmings lace are also produced.

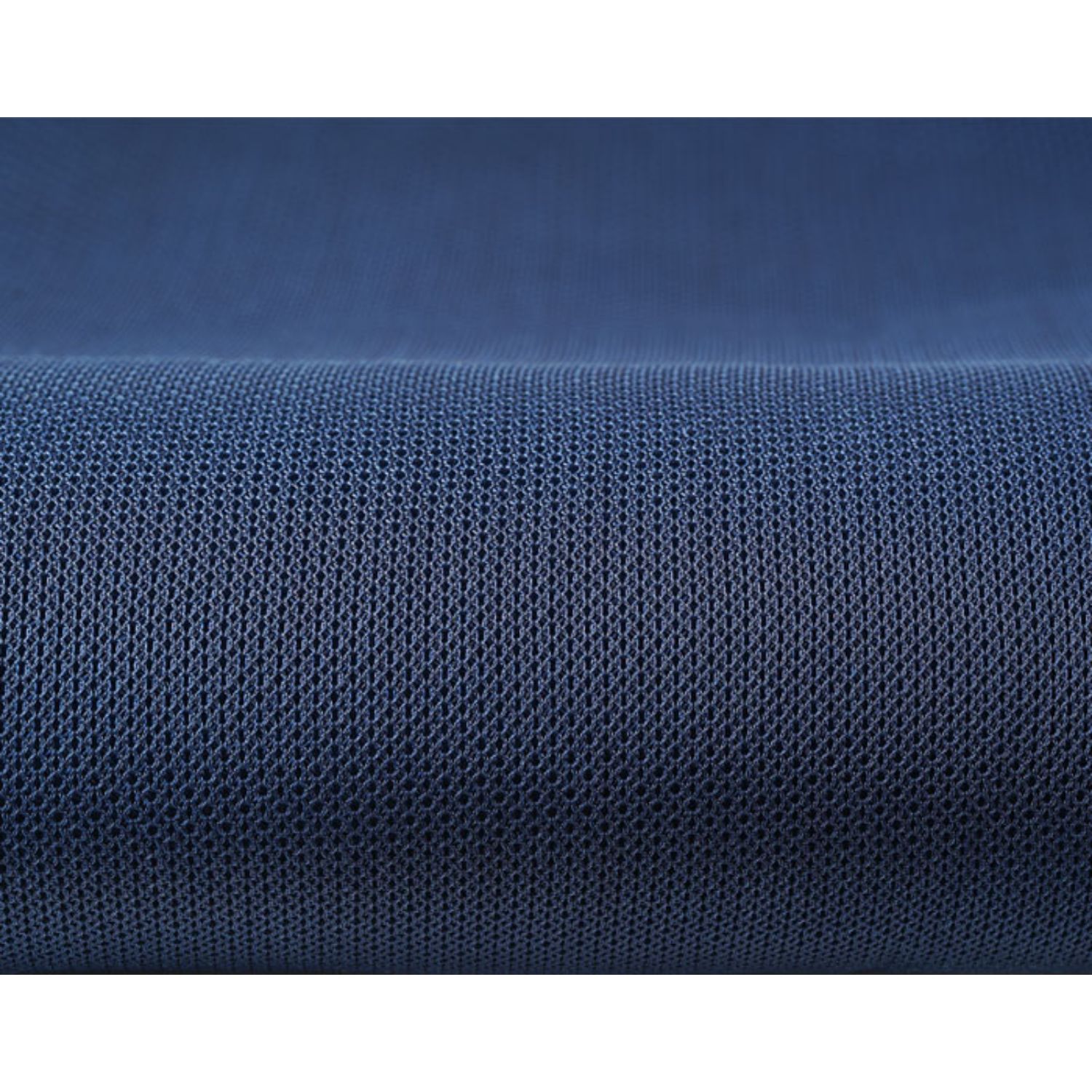

Milanese Knit :

The milanese stitch produces a fabric very similar to tricot. It can be identified by the fine rib on the face & a diagonal pattern on the back. However, milanese fabric is superior to tricot in smoothness, elasticity, regularity of structure & friction resistance.

Warp Knitted Fabric is used for many types of sectors and applications. Such as:

- Inner wears (brassieres, panties, camisoles, girdles, sleepwear, hook & eye tape.)

- Apparel (sportswear lining, track suits, leisure wear and safety reflective vests.)

- Household (mattress stitch-in fabrics, furnishing, laundry bags, mosquito nets, fish nets.)

- Shoes (inner lining and inner sole lining in sports shoes and industrial safety shoes.)

- Automotive (car cushion, head rest lining, sun shades and lining for motorbike helmets.)

- Industrial (pvc/pu backing, production masks, caps and gloves (for the electronic industry.)

- Tricot machines are available in a number of different versions. Depending on the intended end-use and fabric construction, can choose between machines equipped with two, three or four guide bars.

- Specialist machines are also available for producing stretch/non-stretch fabrics.